Basic Knowledge About Stamping Parts Processing

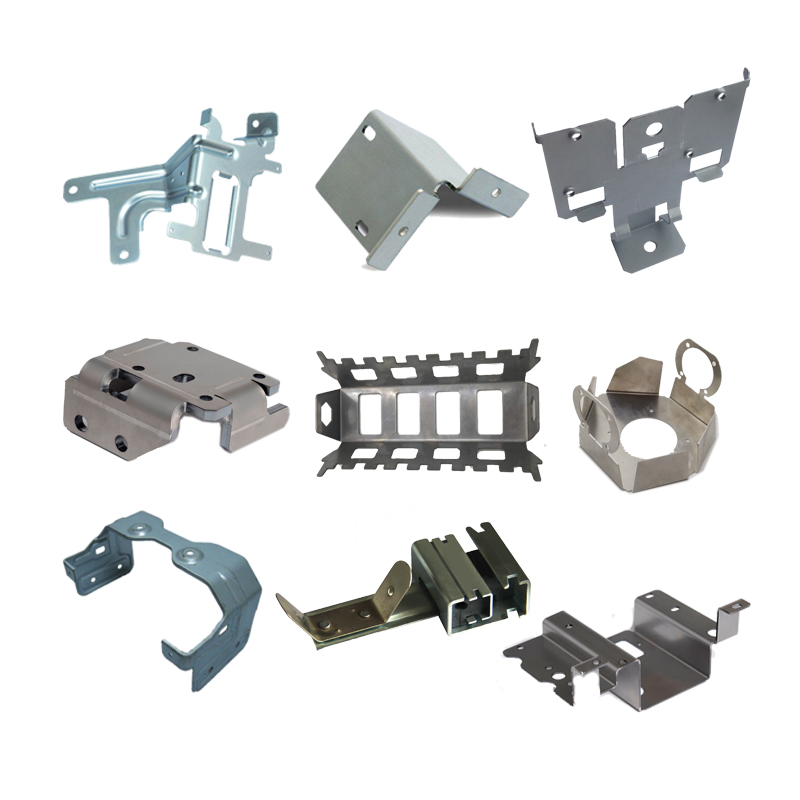

During the stamping process, stamping parts maintain a high surface quality and a smooth, aesthetically pleasing appearance, facilitating painting, electroplating, phosphating, and other surface treatments. Stamping is a production technology that utilizes the power of conventional or specialized stamping equipment to subject sheet metal to direct deformation forces within a die, thereby achieving a desired shape, size, and performance. The sheet metal, die, and equipment are the three essential elements of stamping.

Stamping is a cold metal deformation process, hence the name cold stamping, sheet metal stamping, or simply stamping. It is one of the primary methods of metal plastic working (or pressure working) and falls under the umbrella of material forming engineering technology.

Automobile bodies, radiator fins, boiler drums, container housings, motors, and electrical appliances are all examples of parts that have been stamped. Instruments, home appliances, office machines, and storage containers also contain a large number of stamped parts. Stamping is a highly efficient production process. Using composite dies, particularly multi-station progressive dies, multiple stamping operations can be performed on a single press, enabling automated material generation. Its rapid production, minimal downtime, and low production costs make it a popular choice for many fabricators. Stamped parts, compared to castings and forgings, are characterized by their thinness, uniformity, lightness, and strength. Stamping can also create workpieces with reinforcing ribs, ribs, bends, or flanges, enhancing rigidity, which are difficult to create with conventional tools. By eliminating the need for crude dies, workpiece precision can reach micron levels with high accuracy and consistent specifications, enabling the creation of holes, bosses, and other features.