What are the main advantages of stamping?

Stamping is a highly efficient and widely used metal forming method. Its advantages are mainly reflected in production efficiency, cost control, product quality, and automation potential.

The following are the main advantages of stamping, explained in detail from several core aspects:

1. Extremely High Production Efficiency

This is one of the most prominent advantages of stamping.

High-Speed Production: Ordinary stamping presses can produce tens to hundreds of parts per minute. High-speed stamping is even more impressive, reaching thousands of times per minute.

Mass Manufacturing: Once the molds are made and debugged, identical parts can be continuously and stably produced at a very fast pace, making it ideal for industries requiring large-scale production, such as automotive, home appliances, and electronic products.

2. Excellent Product Quality and Consistency

High Precision and Stability: The precision of stamping dies is very high, ensuring that each stamped part has exactly the same size and shape, resulting in good product consistency and strict tolerance control.

Good Surface Quality: Parts have smooth surfaces and stable quality, typically requiring no additional surface finishing.

High Structural Strength: Through plastic deformation, the material’s grain structure flows and reorganizes along the mold cavity, thereby improving the strength and rigidity of the part.

3. Excellent Material Utilization and Low Cost: The cost advantage is very significant in mass production.

High Material Utilization: Through reasonable layout design (such as cross-layout and mixed layout), waste can be minimized. Waste-free and low-waste stamping technologies can further improve material utilization.

Low Unit Cost: Although the initial manufacturing cost of the mold is high (design, machining, heat treatment), once put into production, the cost per part becomes very low. The larger the production batch, the more prominent the advantage of low unit cost.

Saving Labor Costs: Automated stamping production lines require only a small number of operators and maintenance personnel.

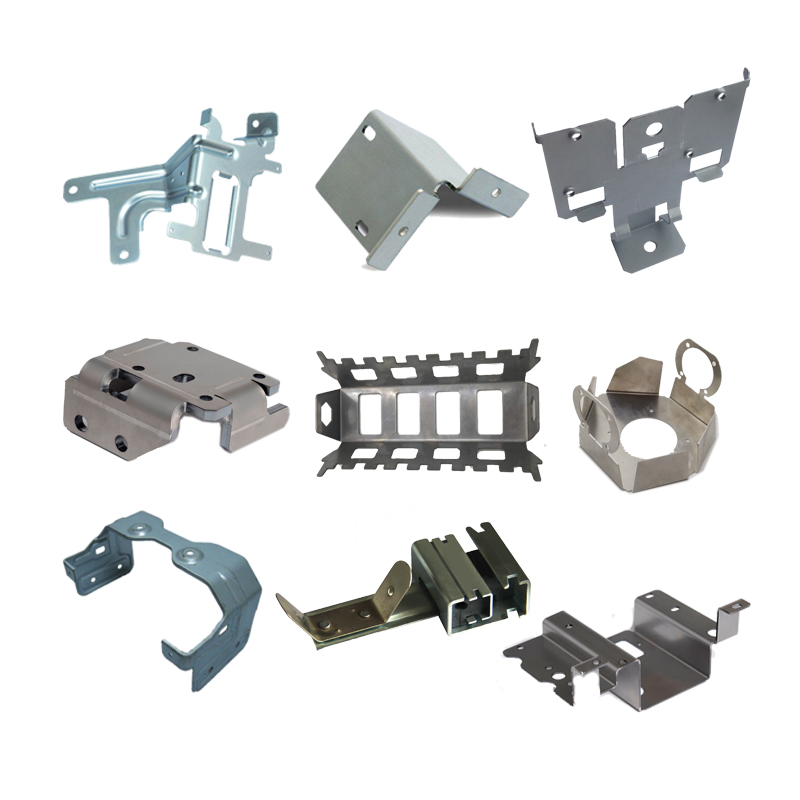

4. Strong Process Flexibility for Manufacturing Complex Parts: Stamping is not limited to simple parts.

Complex Shape Forming: It can manufacture complex shaped parts that are difficult or uneconomical to form using other processing methods (such as machining), such as car doors and chassis shells.

Multiple Process Integration: Stamping is actually a general term for a series of processes, including blanking, bending, drawing, forming, flanging, and necking. These processes can be performed step-by-step on multiple presses or completed in one go on a multi-station progressive die, greatly improving efficiency.

5. Easy Automation and Integration: Naturally Automated Processes: The stamping process (feeding – stamping – output) is very suitable for automation. It can be easily integrated with robotic arms, robots, automatic feeding devices, etc., to form a fully automated production line.

Integration with Upstream and Downstream Processes: Stamping production lines can be easily connected to subsequent processes such as welding, riveting, and painting to form a complete manufacturing system.

6. Other Advantages: Simple Operation: In an automated environment, the skill requirements for operators are relatively low.

Processing of Multiple Materials: Applicable to various metal sheets, such as low-carbon steel, stainless steel, aluminum, copper, titanium alloys, etc., as well as some non-metallic materials.

Summary and Applicable Scenarios

In summary, the core advantages of stamping are: high efficiency, high consistency, low cost (in large-volume production), and the ability to form complex thin-walled parts.

Therefore, its typical applications include:

* Automotive Industry: Body panels (doors, hoods, fenders), chassis parts, etc.

* Home Appliance Industry: Refrigerator shells, air conditioner panels, washing machine drums, etc.

* Electronic Products: Mobile phone frames/back covers, computer cases, connectors, lead frames, etc.

* Aerospace: Various skins and structural components.

* Everyday Products: Metal tableware, watch parts, hardware, etc.

It should be noted that stamping also has its limitations, mainly high mold costs and long manufacturing cycles, making it unsuitable for small-batch or single-piece production. However, for fields requiring large-scale manufacturing, it is undoubtedly one of the most cost-effective and efficient choices.