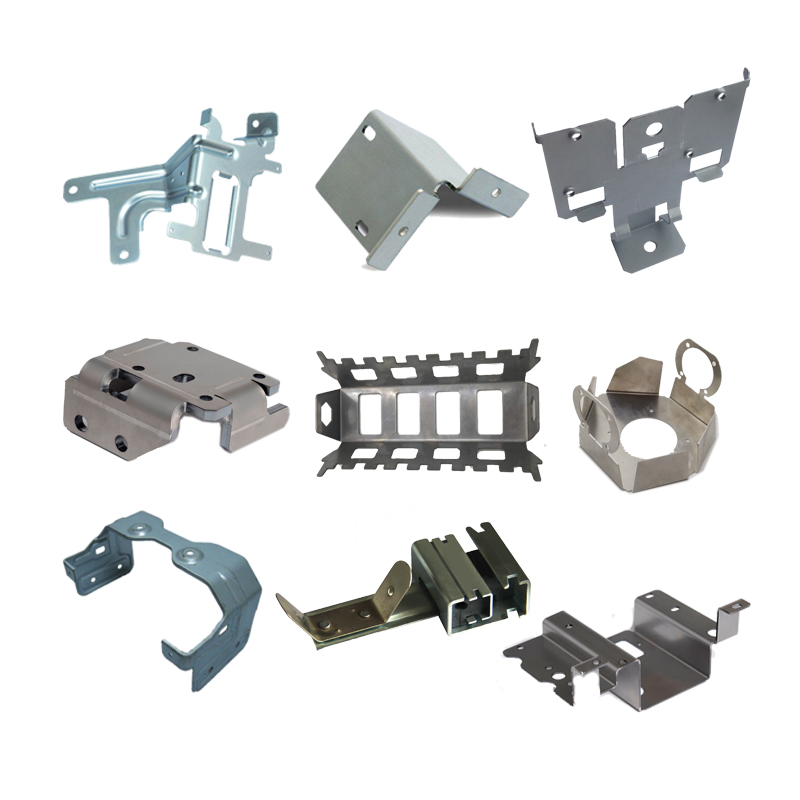

Common Bending Process Types

All sheet metal bending forming methods can be categorized into the following types, from simple to complex, covering 99% of sheet metal bending needs. Your factory’s processing capabilities fully cover these processes:

Basic Bending (Most Common, Accounting for 80%)

90° Right Angle Bending: The most basic type, such as the main body bending of chassis, cabinets, brackets, and shells. All bending is 90°, using a pointed upper die + V-shaped lower die.

Acute Angle Bending (<90°): 45°/60°, such as the bevel of brackets and buckles. The die angle is made to correspond to the acute angle.

Obtonic Angle Bending (>90°): 120°/135°, such as the flange of covers and plates. The die angle is compensated for.

Special Bending Techniques (Advanced Processes, Essential for Factories, Bonus Features)

* **Edge Pressing (Edge Clipping):** Bending once more to press the edge tightly against the sheet metal, with extremely small radius angles. Examples include door panel edging and anti-cut edge folds. Minimum edge depth ≥ 2t. Suitable for sheets with depth ≤ 2mm. Stainless steel edge pressing requires pre-grooving.

* **Arc Bending:** Bending semi-circular/arc edges using an arc mold. No creases. Suitable for exterior parts, handles, and guards.

* **Multi-Bending (Continuous Bending):** For U-shaped, Z-shaped, and box-shaped parts, requiring multiple bends. Pay attention to mold interference; the order is crucial (bend the inner edge first, then the outer edge).

* **Cut-Line Bending:** First, press a shallow groove along the bending line before bending. This solves the problem of a small minimum bending edge and reduces springback. Suitable for precision small sheet metal parts.

* **Crevice-Free Bending:** For stainless steel/ For aluminum sheet metal exterior parts, the mold is covered with a protective film, and the lower mold is fitted with a rubber pad. After bending, there are no indentations on the sheet surface, which is a standard process for high-end sheet metal.