Core Material Selection Principles for Stamped Parts

The core of material selection for stamped parts is matching the stamping process, product performance, and cost, prioritizing metal materials with good plasticity, suitable strength, and stable forming properties.

Core Material Selection Principles

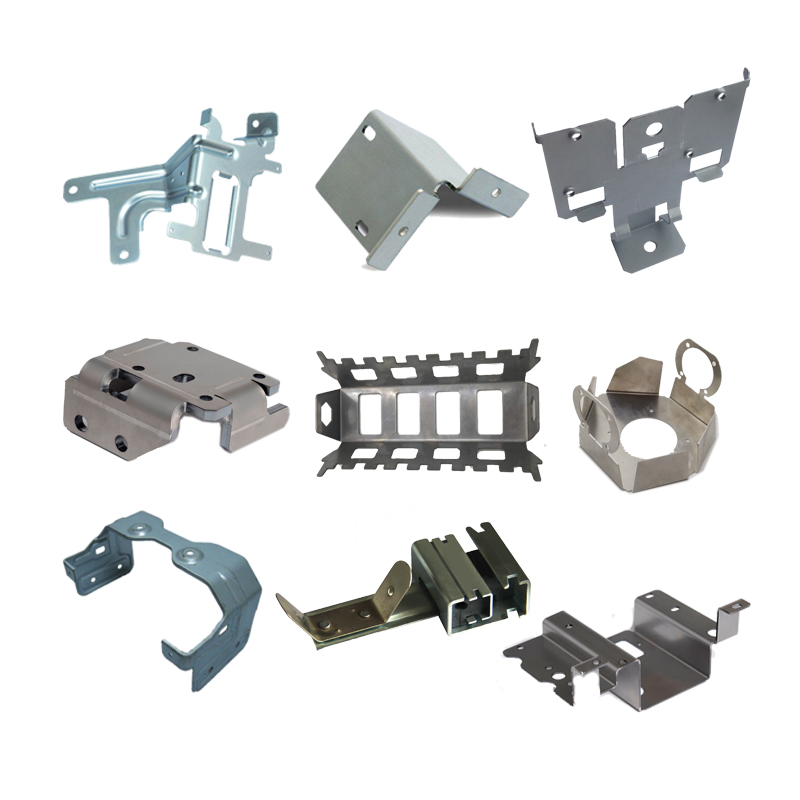

Matching the Stamping Process: Select high-plasticity materials for complex forming processes such as bending and deep drawing; plasticity requirements can be relaxed for simple separation processes such as blanking.

Meeting Product Requirements: Determine key properties such as strength, corrosion resistance, and conductivity based on the application scenario.

Controlling Costs and Machinability: Prioritize materials of common specifications and easy to procure, while also considering compatibility with subsequent welding, painting, and other processes.

Common Materials and Applicable Scenarios

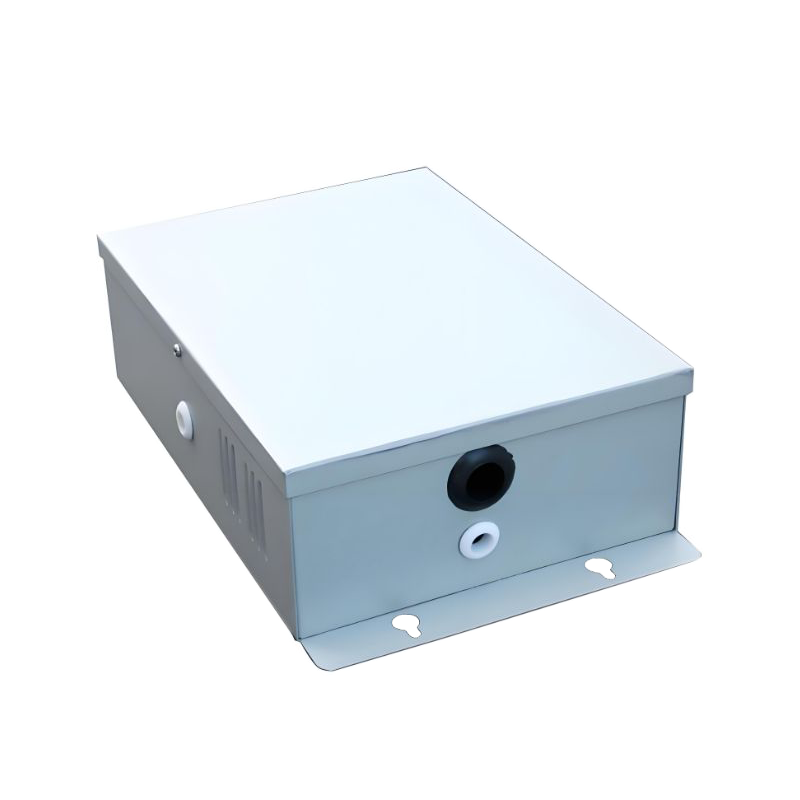

Cold-rolled steel sheets (e.g., SPCC, DC01): Moderate plasticity, low cost, suitable for ordinary stamped parts without complex forming, such as brackets and cover plates.

Hot-rolled steel sheets (e.g., Q235, SPHC): Moderate strength, low price, suitable for thick material blanking and simple bending parts; moderate corrosion resistance.

Stainless steel (e.g., 304, 316): High corrosion resistance and good plasticity, suitable for stamping parts requiring rust prevention, such as those used in food machinery and medical devices; however, it is relatively expensive.

Aluminum alloys (e.g., 6061, 5052): Lightweight, good electrical conductivity, and moderate plasticity; suitable for electronic components and lightweight automotive parts.

Copper and copper alloys (e.g., T2, H62): Excellent electrical and thermal conductivity, and good plasticity; suitable for high-precision stamping parts such as electrical contacts and heat sinks.

Key Material Selection Considerations:

* Plasticity Indicators: Focus on elongation (δ) and yield strength ratio (σs/σb). A lower yield strength ratio results in less springback during forming, making it more suitable for complex deep drawing and bending.

Thickness Tolerance: The uniformity of material thickness directly affects the life of stamping dies and product precision; materials with higher tolerance grades should be prioritized.

Surface Quality: Materials without oxide scale or scratches reduce die wear and ensure product appearance, especially suitable for exposed stamping parts.