Customization Principles of Sheet Metal Source Factory

The core principles of customized sheet metal production at the source factory are controllable quality, optimized cost, guaranteed delivery time, and compliant compatibility. These principles require precise alignment between customer needs and actual production needs.

I. Quality First Principle

Accurate Drawing Implementation: Strictly adhere to the tolerance requirements of customer CAD/PDF drawings. First-piece inspection of critical dimensions is required in advance to avoid batch deviations.

Compliant Material Compatibility: Recommend appropriate sheet metal based on the application scenario (e.g., rust-proof stainless steel, cost-effective cold-rolled steel), provide material certificates, and prevent the use of inferior materials.

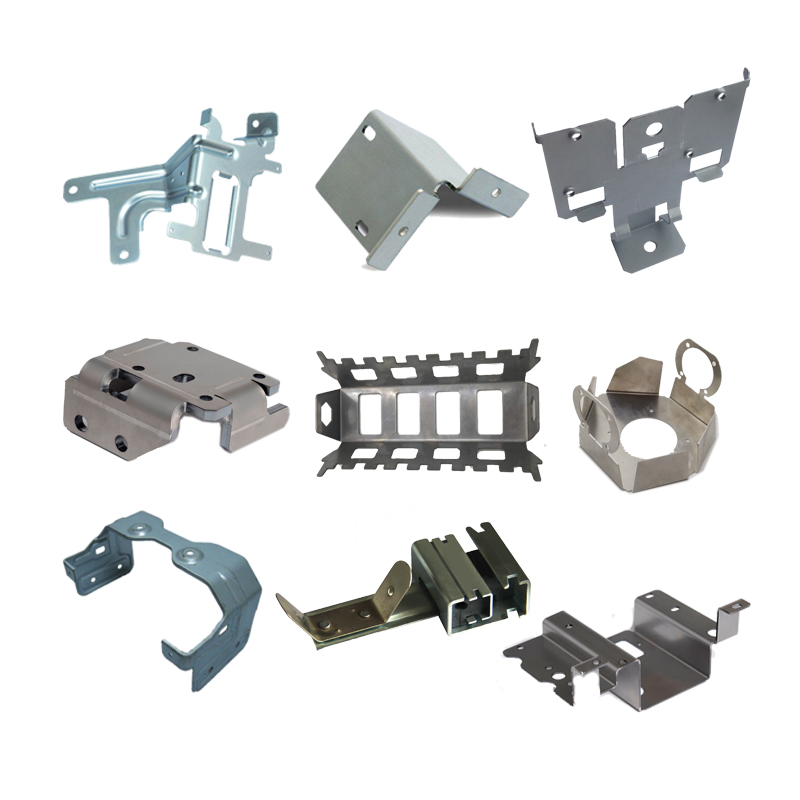

Standardized Processes: Bending, welding, stamping, and other processes follow industry standards. Welded areas require flaw detection. Surface treatments (spraying, electroplating) meet environmental protection and wear resistance standards.

II. Cost Optimization Principle

Design Collaboration and Simplification: Proactively propose manufacturability optimization suggestions, such as reducing complex bending, merging part structures, and reducing production time and material waste.

Tiered Pricing for Batch Sizes: Develop reasonable quotes based on order volume. Larger batches prioritize material utilization, while smaller batches prioritize controlling mold/tooling costs.

Supply Chain Integration: Leveraging our source advantages, we integrate processes such as sheet metal procurement and surface treatment, avoiding markups from intermediaries and improving cost transparency.

III. Delivery Time Guarantee Principles

Precise Capacity Matching: Before accepting orders, we clearly define our own capacity capacity to avoid over-ordering and delivery delays. Delivery milestones are clearly stated in contracts.

Flexible Production Scheduling: Small-batch urgent orders are prioritized for rapid production line activation. Large-batch orders are split into parallel processes, with redundant time allocated for critical processes.

Early Warning of Anomalies: In case of material shortages, equipment malfunctions, or other issues during production, we notify customers within 24 hours and provide alternative solutions to avoid passive delays.

IV. Compliance Adaptation Principles

Industry Standard Alignment: We comply with the customer’s industry standards (e.g., automotive sheet metal must meet TS16949, medical equipment must meet GMP), and provide testing reports.

Environmental and Safety Compliance: The production process meets environmental requirements (e.g., VOC compliance in spraying), and products meet safety standards (e.g., edge deburring, load-bearing capacity).

Confidentiality Agreement: We strictly protect the confidentiality of customer-customized drawings and technical parameters, signing confidentiality agreements to avoid information leakage and infringement risks.

V. Demand Adaptation Principles

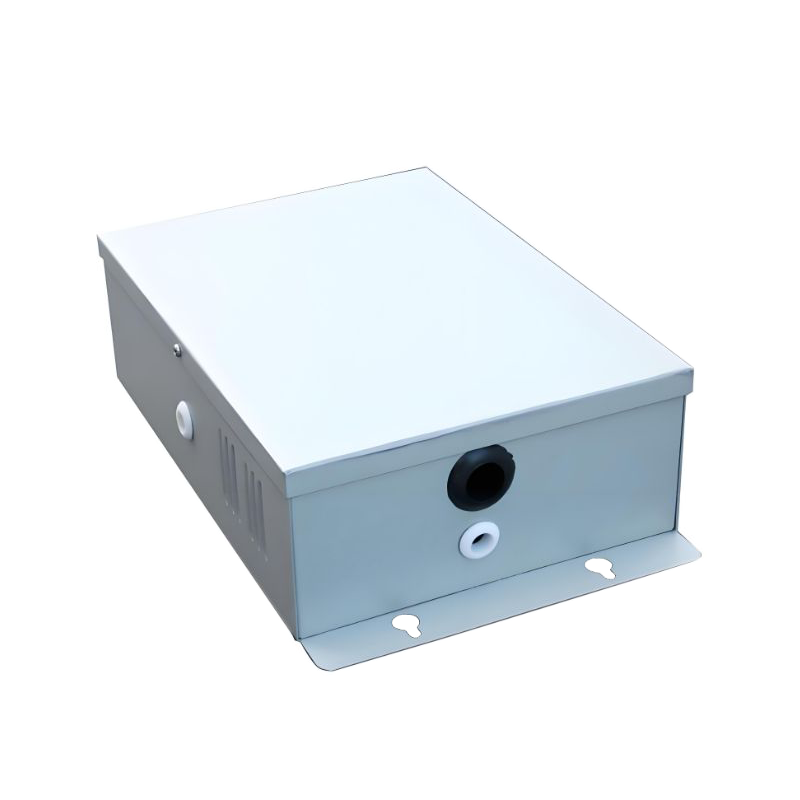

Precise Demand Matching: We confirm the customer’s operating environment (e.g., high temperature, corrosive environments), load requirements, and appearance standards in advance to avoid rework later.

Flexible Customization and Adaptation: We support mixed batch production of multiple varieties and specifications, and provide specialized solutions for special needs (e.g., irregular structures, special surface textures).

Rapid After-Sales Response: We provide installation guidance after delivery. If quality issues arise, we promptly repair or replenish goods according to the contract to ensure a good customer experience.