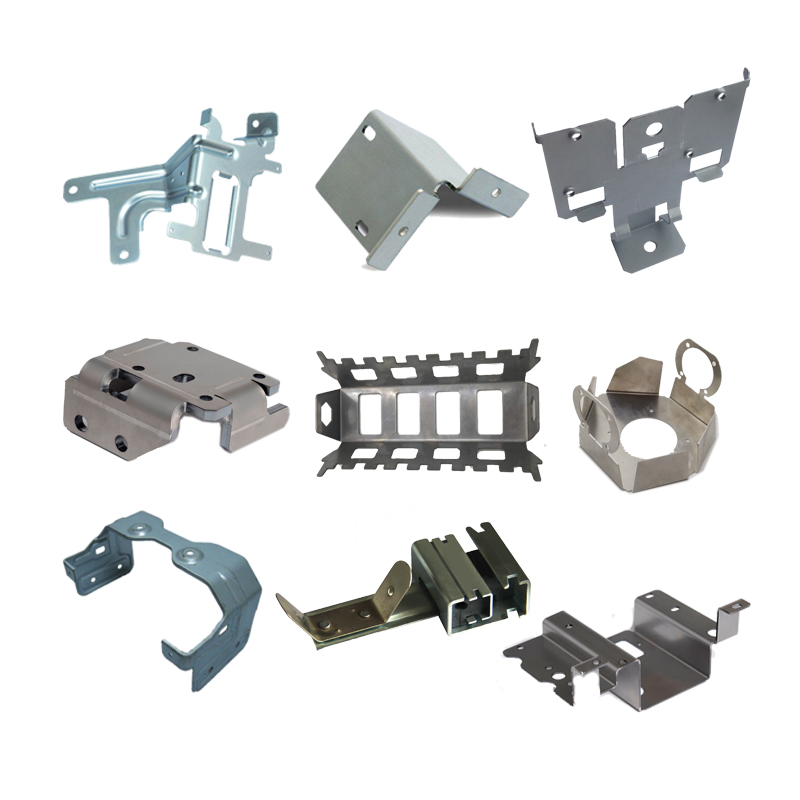

Customization Process for Non-Standard Hardware Parts

Customization of non-standard hardware parts is a demand-driven, multi-stage collaborative process. The core lies in accurately matching customer needs with production processes to ensure the final product meets drawings, performance, and delivery requirements. Below is a standardized breakdown of the entire process, combined with practical points for sheet metal processing and other techniques:

I. Needs Communication and Solution Confirmation (Starting Point of Customization)

Customer Needs Collection

Clearly define the product’s intended use (e.g., industrial equipment parts, automotive components, medical device components) and technical parameters (dimensional tolerances, material requirements, surface treatment, mechanical properties).

Customer-Provided Materials: 2D drawings (CAD), 3D models (SolidWorks/UG), samples, or detailed requirements documents, highlighting key dimensions, tolerance levels, and assembly requirements.

Confirm Batch Size (Prototype/Small Batch/Large Batch), Delivery Cycle, and Budget Range.

Feasibility Assessment

Technical Team Review: Determine the difficulty of material processing, the feasibility of tolerances, and the rationality of the process route (e.g., compatibility with stamping/laser cutting/CNC).

Cost Accounting: A quote based on material costs, processing time, equipment depreciation, surface treatment fees, etc., clearly specifying whether it includes tax/excluding tax and the shipping method.

Final Solution and Contract Signing: Issuance of a technical solution document: including process route, quality standards, acceptance requirements, and delivery milestones.

Signing a Formal Contract: Clarifying the rights and responsibilities of both parties, payment method (advance payment + final payment), and after-sales guarantees.

II. Product Design and Process Planning (Core Technical Aspects)

Drawing Detailing: If the client only provides a requirement description, engineers must complete non-standard design: drawing 2D processing drawings, generating a 3D model, and marking processing benchmarks, tolerance requirements, process holes/positioning holes, and other details.

Design Optimization: Simplifying the structure based on processing technology (e.g., avoiding deep cavities and sharp corners, optimizing bending radii) to reduce production costs.

Process Route Development: Determining core processing steps based on product structure and materials, for example:

Sheet metal non-standard parts: Raw material blanking (laser cutting/shearing) → Bending → Stamping → Welding → Grinding → Surface Treatment.

Non-standard machined parts: Raw material forging/casting → CNC milling and turning → Drilling/tapping → Heat treatment → Surface treatment.

Develop process cards: Clearly define the equipment, parameters, and inspection standards for each process to ensure production consistency.

III. Raw Material Procurement and Preparation

Material Selection and Procurement

Procure raw materials according to drawings: such as cold-rolled steel, stainless steel, aluminum alloy, carbon steel, etc., and provide material certificates (such as RoHS report, material analysis report).

Special Requirements: For materials such as high-temperature resistant and corrosion-resistant materials, confirm supplier inventory and delivery time in advance.

Raw Material Pre-treatment

Sheet/Bar Cutting: Cut or saw according to the blanking dimensions to remove oxide scale and burrs.

Surface Cleaning: Remove oil and rust to prepare for subsequent processing.

IV. Processing and Quality Control

Core Processing Steps

Processing follows the process route. The core processes differ significantly depending on the type of non-standard part:

Sheet Metal Non-standard Parts: Laser cutting (high-precision blanking) → CNC bending (precise angle control) → Welding (argon arc welding/spot welding to ensure weld strength) → Stamping (forming complex structures).

Machined Non-standard Parts: CNC machining (milling, drilling, tapping) → Grinding (high-precision surface treatment) → Heat treatment (quenching/annealing to improve hardness).

In-Process Quality Control (IPQC)

First Article Inspection: The first piece must undergo full-dimensional inspection (using calipers, micrometers, projectors, and coordinate measuring machines) to confirm compliance with drawing requirements before mass production.

Routine Inspection: Sampling inspection is conducted during each batch of production to promptly identify dimensional deviations, surface defects, and other issues, preventing batch scrap.

Record Retention: Inspection reports are completed, and inspection data is retained for traceability.

V. Surface Treatment and Finishing

Surface Treatment: We select processes based on customer needs to improve product corrosion resistance, aesthetics, or functionality:

Protective: Spraying (powder coating/electrostatic spraying), electrophoresis, galvanizing, chrome plating, passivation.

Precision: Polishing, wire drawing, sandblasting (improving surface finish).

Special: Anodizing (aluminum alloy), blackening (carbon steel).

Finishing: Remove burrs and flash from edges and corners; correct assembly dimensions; re-inspect assembly holes and threaded holes to ensure smooth assembly.

VI. Finished Product Inspection and Packaging

Final Quality Control (FQC):

Full Dimension Inspection: Verify that all dimensions and tolerances conform to the drawings.

Performance Testing: Such as hardness testing, salt spray testing (corrosion resistance), load testing (mechanical properties).

Appearance Inspection: Inspect the surface for scratches, deformation, color differences, and other defects.

A factory inspection report is issued and delivered with the goods.

Packaging and Logistics

Packaging Solution: Select protective packaging (bubble wrap, pearl cotton, cardboard box, wooden crate) based on product characteristics to prevent damage and rust during transportation.

Clear Labeling: The outer box should be clearly labeled with the product model, quantity, batch number, customer information, and warning labels (moisture-proof/fragile).

Logistics and Delivery: Ship according to the contract terms (express/logistics/dedicated vehicle), provide tracking numbers, and track delivery progress.

VII. After-Sales and Technical Support

Customer Acceptance: Assist customers with product assembly and debugging, and answer technical questions.

After-Sales Guarantee: In case of dimensional deviations, quality defects, etc., provide repair, rework, or return/exchange services as stipulated in the contract.

Long-Term Cooperation: Establish customer files, conduct regular follow-ups, and optimize product design and processes based on customer feedback.

Key Considerations

Drawing Standardization: Customer-provided drawings must clearly indicate tolerance levels, material standards, and inspection standards to avoid ambiguity.

Process Verification: For complex non-standard parts, it is recommended to make a sample for confirmation before mass production to reduce risk.

Supply chain collaboration: Outsourcing links such as raw materials and surface treatment need to be strictly controlled in terms of delivery time and quality to avoid affecting the overall progress.