Process flow of polishing and deburring stamping parts

1.Manual burr removal

If the burr is large, you can remove the large burr manually first.

2.Belt grinding

You can also use a belt grinding machine to grind off the larger burrs on the workpiece. Removing the obvious large burrs is conducive to further polishing in the grinding and polishing machine.

Choose a grinding and polishing machine

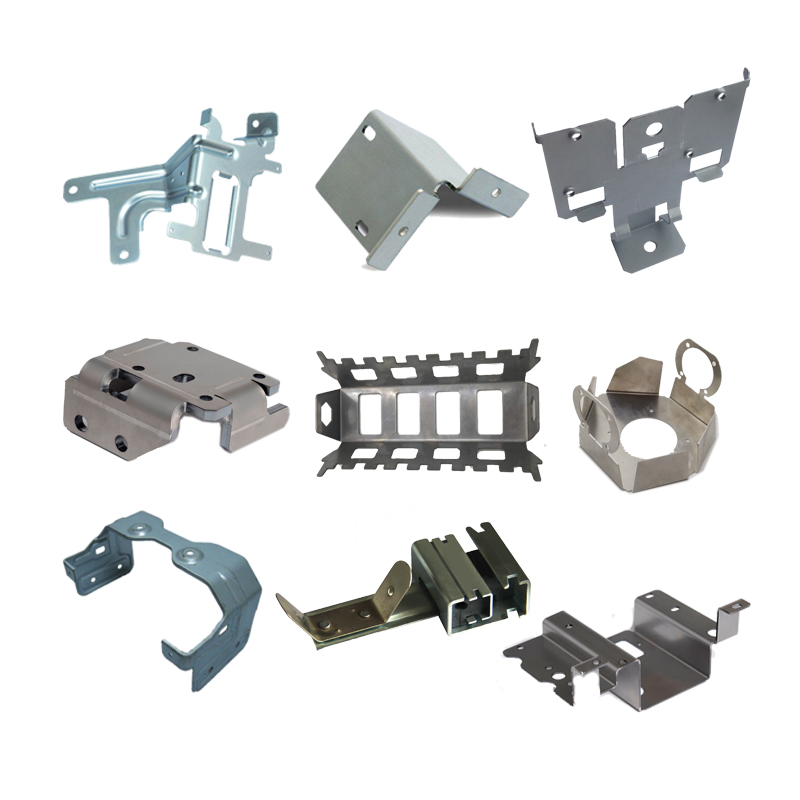

For smaller burrs on stamping workpieces, we can use a grinding and polishing machine to process them in batches. It should be noted that stamping workpieces are large and small, so the correct selection and positioning of the grinding and polishing machine is the key.

3.Use a grinding and polishing machine

Put the workpiece and the grinding medium into the grinding and polishing machine together, and use mechanical movement to make the workpiece and the grinding medium rub against each other, so as to remove the burrs and perform polishing.

4.Fine polishing

After removing the burrs on the surface of the workpiece, the surface of the workpiece must also be finely polished, that is, bright polishing. Bright polishing is different from deburring polishing. In deburring polishing, the grinding media used are grinding and polishing abrasives and polishing abrasives, while in surface bright polishing, grinding and polishing abrasives and grinding brighteners should be used as grinding media. Polishing abrasives are mainly high-aluminum porcelain, high-frequency porcelain, zirconium beads or steel beads. This kind of high-density polishing abrasive is more conducive to the brightness of the workpiece surface.

The basic process flow of stamping parts polishing and deburring. It should be noted that different stamping parts may require different deburring methods and parameter settings, so in actual production, it is necessary to flexibly adjust according to the specific situation.