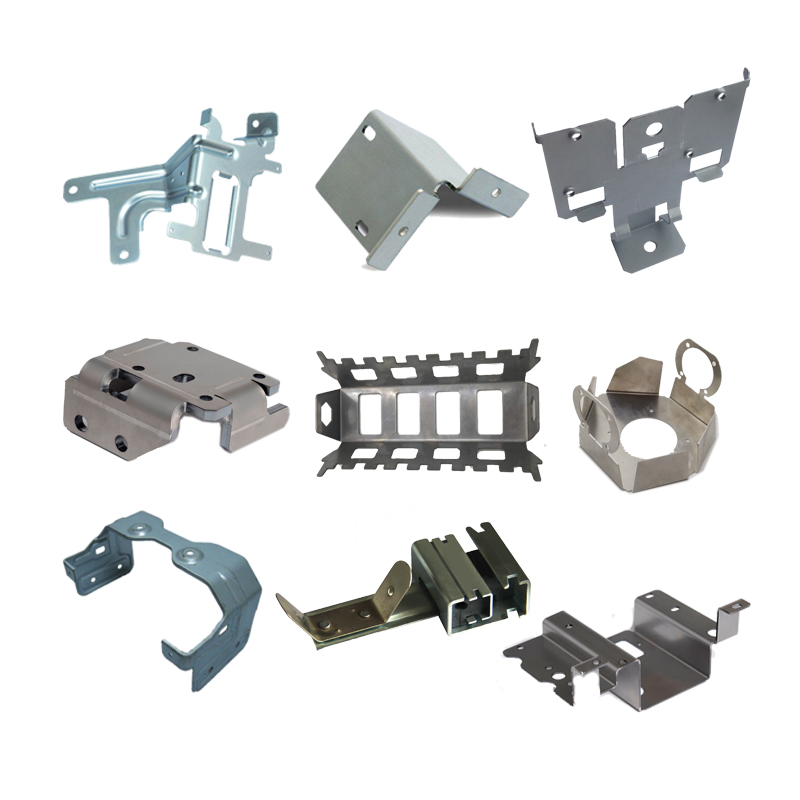

Quality Inspection of Stamped Parts

I. Touch Inspection

Wipe the surface of the outer cover clean with a clean cloth. The inspector, wearing touch gloves, should touch the surface of the stamped part longitudinally. This inspection method depends on the inspector’s experience. If necessary, a whetstone can be used to polish suspicious areas for verification, but this method is still an effective and rapid inspection method.

II. Whetstone Polishing

1. First, wipe the surface of the outer cover clean with a clean cloth, then polish with a whetstone (20x20x100mm or larger). Use a smaller whetstone (e.g., an 8x100mm semi-circular whetstone) for rounded areas and hard-to-reach areas.

2. The choice of whetstone grit depends on the surface condition (e.g., roughness, galvanization, etc.). A fine-grit whetstone is recommended. Polishing should be done primarily longitudinally, adhering well to the surface of the stamped part. For some special areas, transverse polishing can be added.

III. Flexible Sanding Mesh Polishing

Wipe the surface of the outer body panel clean with a clean cloth. Use a flexible sanding mesh to polish the entire surface of the stamped part longitudinally, close to the surface. Any pits or indentations will be easily detected.

IV. Oiling Inspection

Wipe the surface of the outer body panel clean with a clean cloth. Then, use a clean brush to evenly apply oil to the entire outer surface of the stamped part in the same direction. Inspect the oiled stamped part under strong light; it is recommended to hold the stamped part upright in front of the vehicle body. This method can easily detect tiny pits, dents, and ripples on the stamped part.

V. Visual Inspection

Visual inspection is mainly used to detect appearance abnormalities and macroscopic defects in the stamped part.

VI. Fixture Inspection

Place the stamped part in the fixture and inspect it according to the fixture’s instruction manual.